Classification of parts in large CNC machining center!

Large CNC machining centers have many processing procedures, high requirements, need many types of general machine tools tool clamps. They also need repeated clamping adjustment before finishing machining. They need many parts to be combined. So this article focuses on introducing the classification of parts in large CNC machining centers, hoping to help us.

The primary target of its processing includes five categories: box type parts, disordered surfaces, special-shaped parts, plate sleeve type parts special processing.

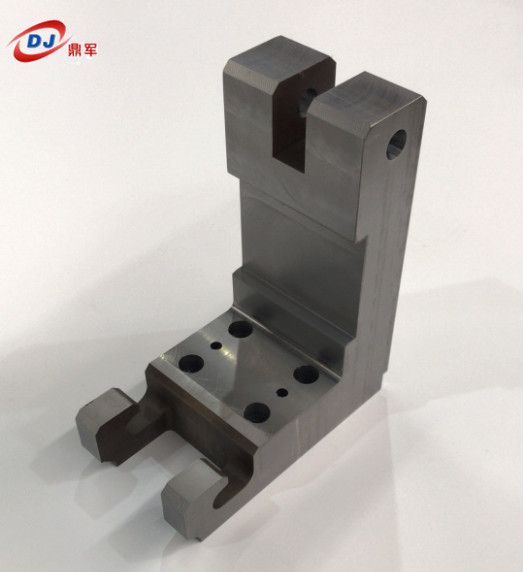

Box type parts generally refer to parts with more than one hole system, internal cavity, a certain share in the direction of length, width height. This kind of parts are widely used in machine tools, cars, aircraft manufacturing other professions. Box type parts generally require multi station hole system plane processing, with high requirements for public service, especially for shape position. Generally, they need to go through milling, drilling, expanding, boring, reaming, spot facer, tapping other processes. They need more cutting tools, are difficult to process on general machine tools, have many sets of tooling, high cost, long processing cycle, need to be clamped, aligned measured manually Because of the large number, the cutting tools must be changed frequently during machining. It is difficult to draw up the technology , more importantly, to ensure the accuracy.

For the CNC machining center processing box type parts, when there are many machining stations, the horizontal boring milling machining center is generally selected for the parts that need the worktable to rotate the point of view repeatedly. When the number of processing stations is small the span is large, the vertical machining center can be selected to process one end.

The disordered surface plays an important role in the mechanical manufacturing industry, especially in the aerospace industry. It is difficult even impossible to finish the selection of general machining methods for the disordered surface. In China, the traditional method is to the precision casting, which can be imagined that the precision is low. Disordered surface parts such as various impellers, guide wheels, spherical surfaces, various surface forming dies, propellers of propeller underwater vehicles, some free-form surfaces of other shapes. These parts can be processed by machining center. The typical ones are as follows:

As the basic component of mechanical information storage transmission, it is widely used in various kinds of automatic machines. Such parts include disc cams with various curves, cylindrical cams, conical cams, barrel cams, end cams, etc. For machining such parts, three-axis, four-axis linkage five axis linkage machining center can be selected according to the disorder degree of cam.

This kind of parts are commonly used in compressor of aeroengine, expander of oxygen making equipment, single screw air compressor, etc. for such a profile, the machining center with four more axes linkage can be selected to finish. CNC machining of parts

Such as injection mold, rubber mold, vacuum forming blister mold, refrigerator foam mold, pressure casting mold, precision casting mold, etc. Selecting the machining center to process the mold, because the process is highly centralized, the finishing of key parts such as dynamic mold static mold is basically the completion of all machining content in one installation, which can reduce the accumulated dimension error repair workload. Together, the mold can be copied, interchangeability is good. The amount of work left by machining to the fitter is small. the cutting tools are accessible, the machining shall be completed as far as possible. In this way, the work of the die fitter mainly depends on polishing.

Another problem is that after understanding mastering the machining procedures of large CNC machining centers, operators can still finish a lot of processing, for example, some special process manufacturing, such as lettering on metal surfaces, etc. in CNC machining centers other process operations can be very convenient.

Contact: Manager Cao Mobile phone:(+1)7177019147

Email: janetcao23@gmail.com